While measuring your garage or workshop, take into account any obstructions such as garage door openers, door tracks, stairs, etc.

Make sure your garage is wide enough to fit your new hoist. Survey your garage or workshop area for such items as shelving or work benches that will prevent the hoist from being installed or properly operated.

You must be able to fit the hoist within your garage and the depth of your garage will determine which hoist is most suitable. Once again, think about any potential obstructions that may prevent the hoist from being properly installed and operated.

Your hoist has specific requirements to secure safely to a concrete base. Make sure your concrete is thick enough to support your hoist, minimum thickness is 100mm. Also, ensure your concrete is in good condition with no major cracks. For example, concrete anchors must be at least 150mm from the edge of the concrete or any seam and the hoist cannot be anchored to the concrete if there are any cracks within 900mm of the base plate.

You need to make sure your vehicle will fit onto the hoist and that there is adequate clearance when the vehicle is in the hoisted position. Also, make sure the hoisting capacity of the hoist is properly matched up with your heaviest vehicle.

You need to make sure there is enough clearance in your garage. Remember to take into account remote panel doors when open.

You need to make sure your vehicle will fit onto the hoist.

Choosing the proper hoist is determined by what you are planning to do with it. Are you primarily going to use the hoist for vehicle storage and occasional repair work? Will you frequently be removing the wheels from the vehicle?

You will need to consider your power requirements, 240V or 3 Phase. Please discuss with an electrician.

All Tufflift hoists are available with either a 240V or 3 Phase power unit at no extra cost and you will need an electrician to wire the unit.

All Tufflift hoists are supplied with Tufflift Hydraulic 32, additional oil can be purchased from Tufflift in 6 litre containers.

Our installer’s use a 20 mm drill bit to drill the holes for the dyna bolts.

Sizes vary depending on the hoist model. They are typically 18mm or 20mm in diameter, with the length also differing by model. Additional bolts can be purchased from Tufflift.

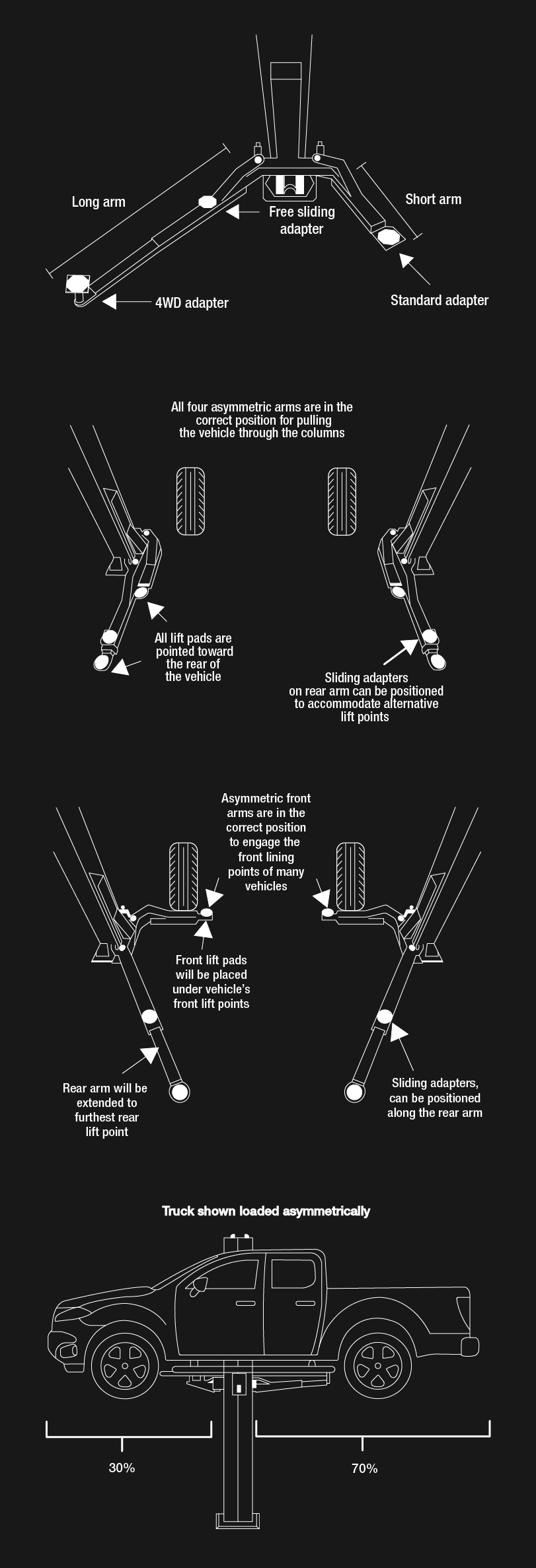

Asymmetric or symmetric refers to the column configuration or the arm configuration of a car hoist. A two-post car hoist is designed to fit a range of car widths between them, but some with symmetrical arms (all four arms are of equal length) make it difficult to open a driver’s door to gain access to the vehicle, as the post obstructs it from opening wide when the vehicle is raised, therefore the width between the posts need to be made wider.

By making shorter arms for the front and longer arms for the back (asymmetric arm configuration), this allows a vehicle to be positioned between the columns with approximately one third of the car in front of the column and two thirds behind the column. To properly load any vehicle onto an asymmetric hoist, all the arms with lift pads need to be pointing toward the rear of the vehicle.

The shorter arms would then be pulled forward and the lift pads positioned on the appropriate forward lifting points. Similar with the rear arms positioned at the lifting points near the rear of the vehicle. This configuration would allow the driver’s front door to open wider clearing the columns giving better access to the inside of the vehicle if required.

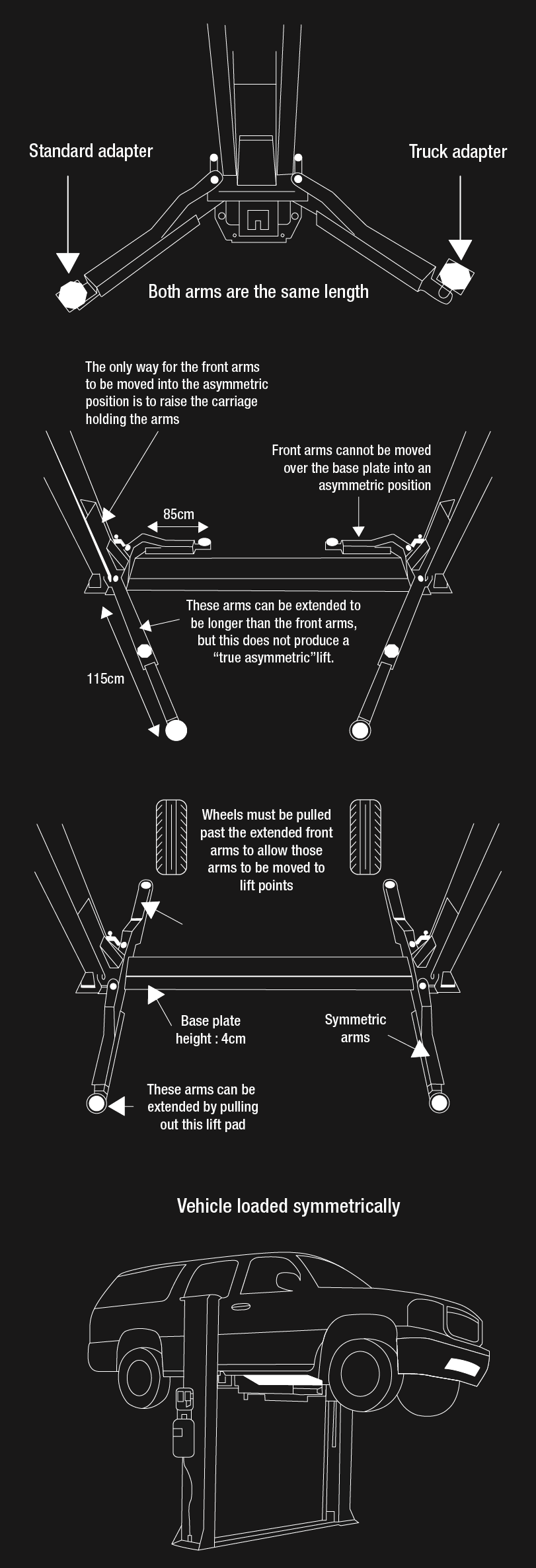

There are two kinds of two-post hoists – 1) with cables and hoses running along the floor with a protective cover or plate, this is known as a base plate model and 2) one with cables and hoses running across the top of the hoist leaving the floor clear for equipment to move unimpeded under the vehicle, known as a clear floor model. The weight of a vehicle must be evenly distributed on each of the four arms of a two-post hoist whether it be a symmetric or asymmetric configuration. A base plate hoist can have short front arms and long rear arms, but this does not make the base plate lift asymmetric, as the front arm pads could not be moved to face the rear of the vehicle due to a raised metal base plate on the floor between the two columns. This initial positioning of the arms is only possible on an overhead style two-post hoist which is preferred for lifting heavier vehicles.

Symmetric arms on a two-post hoist can be extended or retracted so that all four arms are the same length, allowing a vehicle to be raised in the middle of the hoist which is preferred for longer vehicles.

Symmetric columns are installed so that the middle of the columns are positioned directly across from each other allowing a wider space to drive through.

All hoists come with a comprehensive step-by-step installation guide which allows easy assembly by one person. All hoists are designed to be installed inside a garage or workshop. Installation outdoors will void the warranty as none of the components are designed to be in wet or extremely humid conditions. Only the two post hoists are required to be anchored to the floor. Four post parking hoists do not require anchoring unless floor slope is greater than 1/8” per metric. If the hoist is to be anchored to a floor which has infloor heating, the routing of the heating system must be known to make sure it is not damaged when the anchors are driven into the floor.

Tufflift also offers an installation service in most States, so contact the customer support team on 1800 88 33 50 and they can assist in helping you arrange installation.

Yes, we can arrange a freight quote for delivery anywhere in Australia. Contact our team, and we’ll provide a detailed quote for your location.

No, Tufflift does not offer free shipping. The customer is responsible for covering the freight cost, which will be included in your quote.

Freight costs depend on the destination, item size, and weight. Tufflift is dedicated to offering the most efficient and cost-effective quotes for our customers. Our team will provide a specific quote based on these factors to ensure an accurate delivery cost for your order.

While we can handle the freight arrangements, you're welcome to organize your own shipping if preferred. Just let us know your preference, and we’ll coordinate accordingly.

If your Tufflift product arrives damaged, please contact our customer service team immediately. Provide details and photos of the damage, and we will assist you in resolving the issue promptly.

First, check the troubleshooting section in your owner’s manual. If the issue persists, contact our customer support team at 1800 88 33 50 for further assistance.

Yes, Tufflift offers after-sales service for the repair or replacement of worn or faulty hoist parts. Our team can help ensure your hoist remains in top condition. To place a service inquiry, you can contact us at 1800 88 33 50 or through the contact form on our Service Page Enquire now

We recommend using ISO46 hydraulic fluid in all Tufflift hoists for optimal performance and durability.

Yes, Tufflift has a team of in-house technicians as well as a nationwide network of qualified technicians. This ensures that you receive quick and efficient support for servicing and maintaining your hoist, no matter where you are located.

Regular maintenance is key for safety and performance. We recommend scheduling a maintenance inspection every 12 months to ensure your hoist operates at its best and remains compliant with safety standards.

Look for signs like unusual noises, slow lifting or lowering, hydraulic fluid leaks, or uneven lifting. If you notice any of these issues, it’s best to stop using the hoist and arrange for an inspection.

Yes, Tufflift provides a range of spare parts for various hoist models. Our parts are designed for durability and compatibility to ensure your hoist continues to function smoothly and safely.

Check the model number on your hoist and refer to models listed under the part description on the product page. If you’re unsure, our team is here to help you find the right part based on your hoist’s specifications.

This could be due to low hydraulic fluid, worn-out components, or a mechanical issue. Start by checking the hydraulic fluid level and inspect for visible wear or damage. If the problem persists, contact us and we can organise one of our technicians to come out for a thorough inspection and repair.

Yes, Tufflift hoists are built to comply with Australian standards, ensuring safety and quality in both commercial and industrial applications. Documentation such as engineer certification and Worksafe Design Registration certificates is also available.

Tufflift offers a limited warranty on all products

- EAE 2 and 4 post hoists: 5-year structural warranty, 24 month warranty on electrical, mechanical and hydraulics, covering both parts and labor.

- Tufflift 2 and 4 post hoists: 5-year structural warranty, 12-month warranty on electrical, mechanical and hydraulics, covering both parts and labor.

- Mid-rise hoists: 5-year structural warranty, 24-month warranty on electrical and hydraulics, covering both parts and labor.

Motorcycle hoists, rotisserie units, jacks, and accessories: 12-month structural warranty.

To make a warranty claim, please contact Tufflift at 1800 88 33 50 or email serviceteam@tufflift.com.au with details such as your hoist model and serial number.

testing to verify strength, integrity, and compliance with specified lift weight capacities, ensuring high safety standards.

Yes, for additional details on compliance, please check with your state’s Workcover Authority to ensure all requirements are met in your specific region.

Tufflift, in partnership with Emu Money, provides a range of commercial finance options, including rental, chattel mortgage, and business cash loans to meet various business needs.

Both start-ups and established businesses are eligible to apply, with flexible options to support different business structures and financial situations.

Financing terms range from 12 to 60 months, allowing you to select a payment plan that suits your business’s budget and cash flow needs.

Tufflift offers fast approvals, making it easy to acquire the equipment you need without delay.

Leasing offers several benefits: no initial deposit (other than the first month’s lease payment), cash-flow-friendly monthly payments, and a lease-to-own option, allowing you to own the equipment at the end of the lease.

Yes, leasing is typically 100% tax-deductible if the equipment is used for business or income production, as the lease payments are generally fully deductible.

Absolutely. Tufflift offers 3, 4, or 5-year lease terms, allowing you to select a term that matches your budget, with longer terms resulting in lower monthly payments.

Yes, Tufflift offers personal finance options through Emu Money & Humm90, making it easier for motor enthusiasts to acquire the equipment they want with flexible repayment plans.

Terms range from 6 to 60 months, allowing you to structure a repayment plan that best fits your budget.

To apply, you must be at least 21 years old, an Australian citizen or permanent resident, have a regular source of income, and a good credit history.

You can obtain a risk-free rate quote online through Emu Money’s platform. This allows you to explore competitive options before proceeding with your purchase.

CONTACT US